Hot melt packaging has emerged as a go-to technology for secure and sustainable bonding in today’s fast-paced industrial environments where speed, efficiency, and reliability are non-negotiable. From carton sealing to label application, hot melt adhesives have revolutionised how products are packaged, shipped, and presented, especially in food, pharmaceuticals, and e-commerce sectors. Without it, boxes would fall apart, labels would peel off, and the entire supply chain would crumble. While various adhesive types exist, hot melt adhesives play a vital role, particularly in “hot melt packaging”.

In this article, we’ll explore what hot melt packaging is, how hot melt adhesives function, the role of industrial packaging adhesives in case sealing, and the different packaging glue solutions available today.

Hot melt packaging refers to the use of thermoplastic adhesives, commonly known as hot melt adhesives, in various packaging applications. Hot melt adhesives are typically applied at temperatures between 120°C and 180°C. Once cooled, they offer instant bonding, eliminating the lengthy curing times associated with other adhesive types, such as water-based or solvent-based alternatives.

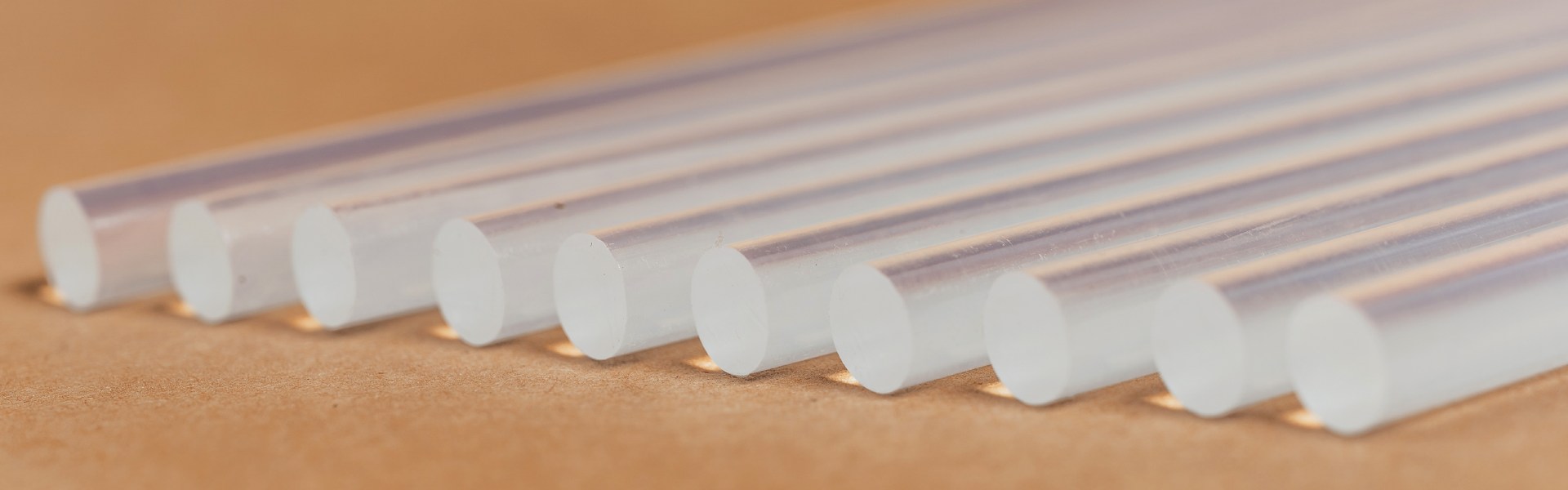

Solid at room temperature, these adhesives melt into a liquid state when heated, becoming sticky and capable of bonding to a wide range of substrates. Upon cooling, they quickly solidify, forming a strong and durable bond. This process is widely used in the packaging industry because it enables fast-setting, tamper-resistant, and versatile bonding across various materials like cardboard, plastics, and coated papers.

Think about the last time you opened a cardboard box. Chances are, the flaps were secured with hot melt adhesive. This is just one example of the widespread use of hot melt packaging, which extends to a vast range of applications.

Hot melt adhesives are not a one-size-fits-all solution. They are formulated to meet different application needs. Key types of hot melt adhesives used in packaging include:

These adhesives are not only efficient but are also engineered to minimise carbon footprint by reducing energy usage and material waste in production.

The selection of the appropriate hot melt adhesive depends on several factors:

One of the most critical applications of hot melt adhesives in packaging is “case sealing”. Securing corrugated boxes and cartons effectively is paramount for preventing damage and pilferage during shipping and handling. Hot melt adhesives provide a fast, reliable, and cost-effective solution for this crucial task.

Ideal case sealing adhesives possess the following characteristics:

These adhesives are compatible with automated case erectors and sealers, making them indispensable across various industries, including food and beverage, consumer goods, pharmaceuticals, and e-commerce. They are a fundamental aspect of industrial packaging, contributing significantly to the smooth flow of goods through the supply chain.

The versatility of hot melt adhesives extends far beyond case sealing. They are utilised in a wide array of packaging applications, including:

Innovative packaging designs often leverage the unique properties of hot melt adhesives to create visually appealing and functional solutions. For example, hot melt adhesives can be used to develop tamper-evident packaging, child-resistant closures, and easy-open features.

Choosing the right packaging glue solution depends on various factors, including substrate material, production speed, environmental exposure, and recyclability requirements. Modern hot melt solutions address a wide range of challenges:

| ADHESIVE TYPE | BEST FOR | NOTABLE FEATURES |

| EVA Hot Melt | Corrugated box sealing | Fast set time and cost-effective |

| Metallocene Hot Melt | High-speed automated packaging | Low char, clean running and low odour |

| Polyamide Hot Melt | Electronics and difficult plastics | Excellent chemical and heat resistance |

| Pressure-Sensitive Hot Melt | Labels, tapes, hygiene packaging | Resealable, flexible, and removable |

Custom blends are also available for specialised industries, such as pharmaceutical compliance (FDA or EU certifications), food-safe contact, or compostable packaging.

Hot melt packaging is an indispensable part of the modern supply chain. It is more than just an adhesive technique—it’s a strategic enabler for efficient, sustainable, and high-performing industrial packaging. From securing cardboard boxes for shipping to adhering labels to consumer products, hot melt adhesives play a critical role in ensuring the safe and efficient delivery of goods to consumers. The right packaging glue solutions are central to operational success.

From energy efficiency and cost savings to high-speed automation compatibility, hot melt technologies are shaping how modern businesses seal and secure their products. As demand grows for recyclable, tamper-evident, and low-impact packaging, industrial packaging adhesives will continue to adapt and evolve, ensuring that our goods are securely bonded and reach their destination safely and intact. Finding the right packaging glue solutions in collaboration with an experienced adhesive manufacturer is key to success.